What It Does

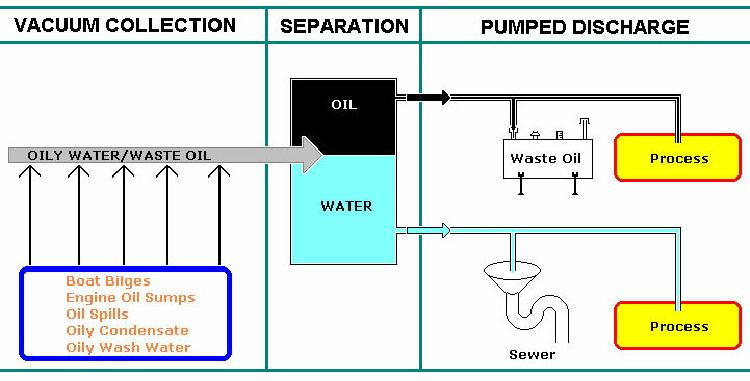

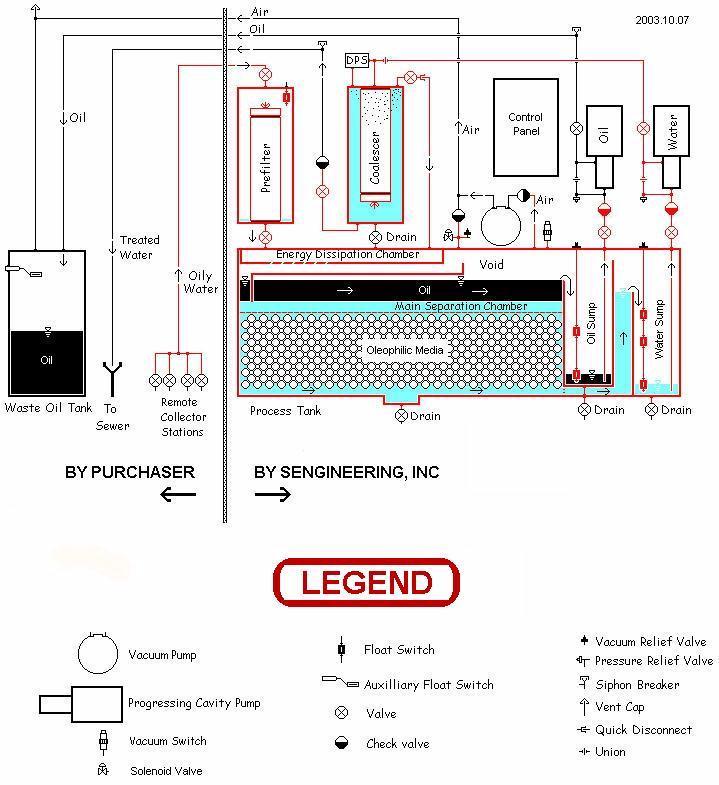

VACUUM COLLECTS OILY WATER AND WASTE OIL at its source through a network of customer-provided hard-piped collector stations and hoses, into a remote, centrally located, 105 gallon system vacuum tank. Compared to other liquid conveying methods, vacuum collection offers the following advantages:

SEPARATES OIL FROM WATER by combining 4 routinely used physical technologies in 3 sequenced stages which progressively reduce oil in water concentrations. NOTE: Additional subsequent treatment and separation stages are possible/optional:

- Infinite collector station configurations.

- Manual or automatic flow activation and control. User operated valves at hose ends are the most common.

- Continuous or intermittent flow.

- Simultaneous operation of multiple collector stations.

- Dry lift heights to 25 feet.

- Horizontal runs hundreds of feet away from vacuum source.

- Minimum probability of accidental leakage to the environment.

- Minimal undesirable liquid agitation.

- No need for any additional pumps or equipment.

SEPARATES OIL FROM WATER by combining 4 routinely used physical technologies in 3 sequenced stages which progressively reduce oil in water concentrations. NOTE: Additional subsequent treatment and separation stages are possible/optional:

|

Stage

1 2 3 4 (Opt) |

Type

Physical - Static Physical - Dynamic Physical - Dynamic Physical/Chemical |

Technology

o Vacuum induced low grade dissolved air flotation o Differential specific gravity/quiescent separation Oleophilic media contact entrapment Pressure screening through conventional coalescer filter elements Oil-selective media adsorption, ultrafiltration, etc |

DISCHARGES WASTE OIL (almost water-free) into storage facility(s) for further use, resale, disposal, reclamation, or treatment.

DISCHARGES TREATED WATER (only slightly contaminated, typically 5 - 15 ppm oil if not chemically emulsified) directly to sanitary sewers (legal in most communities) or to storage facility(s) for further use, reclamation, or treatment.

DISCHARGES TREATED WATER (only slightly contaminated, typically 5 - 15 ppm oil if not chemically emulsified) directly to sanitary sewers (legal in most communities) or to storage facility(s) for further use, reclamation, or treatment.

FEATURES

- Fully Automatic. No equipment operator or attendant required. System vacuum is always available, and is automatically and constantly regulated. Separated water and oil discharge also occurs automatically.

- Compact Size. 67" H x 72" W x 28" D. About 750 lb dry weight.

- Fail Safe. Power interruptions will not cause malfunctions or otherwise create unsafe conditions.

- User Friendly. As easy to use as a household vacuum cleaner. Control panel lights indicate various pump running conditions, full waste oil storage container(s), and need for prefilter element and coalescing filter element replacement.

- Trouble Free. Fabricated from highest quality materials and components readily available from numerous vendors to ensure reliable, consistent performance. Wetted parts and materials are either PVC, cast iron, or brass for long life. Few moving parts.

- Easy, Infrequent, Inexpensive Maintenance. Routine maintenance limited to replacing prefilter element and coalescing filter element (about 1x/year @ about $25/interval). Filter elements replacement is simple, non-messy, convenient.

- Low Operating Costs. Depending on local electric utility rates, about $300/year.

- Environmentally Correct. Complies with all life safety codes and environmental laws and regulations.

Benefits of Ownership

- Profit Center for Marinas, Boat Yards, and Yacht Clubs. Can provide very high return on investment (RORs up to 50%) and increased profits through 1) modest slip/berth fee surcharges in return for customer unlimited use of the system, 2) per-use fees, or 3) a combination thereof.

- Pollution Fine Avoidance. Can eliminate or minimize exposure to expensive fines and penalties ($25,000 per day in some extreme cases) that are possible from oftentimes confusing and complicated array of Federal, State, and local laws and regulations.

- Emergency On-Site Spill Response Capability. Provides on-site immediate response capability to combat oil spills and accidental discharges; helps mitigate any consequent fine and penalty threats by regulators and enforcement officials.

- Competitive Advantage. Redefines Full Service/World Class Marina. Gain that elusive competitive edge, PR, and marketing advantage by offering an environmentally conscious, safe, simple, desirable and reliable service for your customers.

- Demonstrated Environment Stewardship. Helps protect the marine environment.

- Cleaner Harbors and Boat Basins. Helps prevent annoying, unsightly, and difficult to clean oil stains on boat hulls, pier structures, floating docks, and shorelines.

|

Sengineering, Inc. Provides

|

Customer Provides

|

|

|

ORDERING INFORMATION

Price: $21,975** FOB Bellingham, WA

(**Quantity Discounts Available)

Delivery Time: 12 weeks ARO